|

MS-Smart2

The new tilt camera developed with new design concept supports image-free operation, stable performance and good use experience

|

|

New features and new changes

|

|

|

|

|

New composite process body shell |

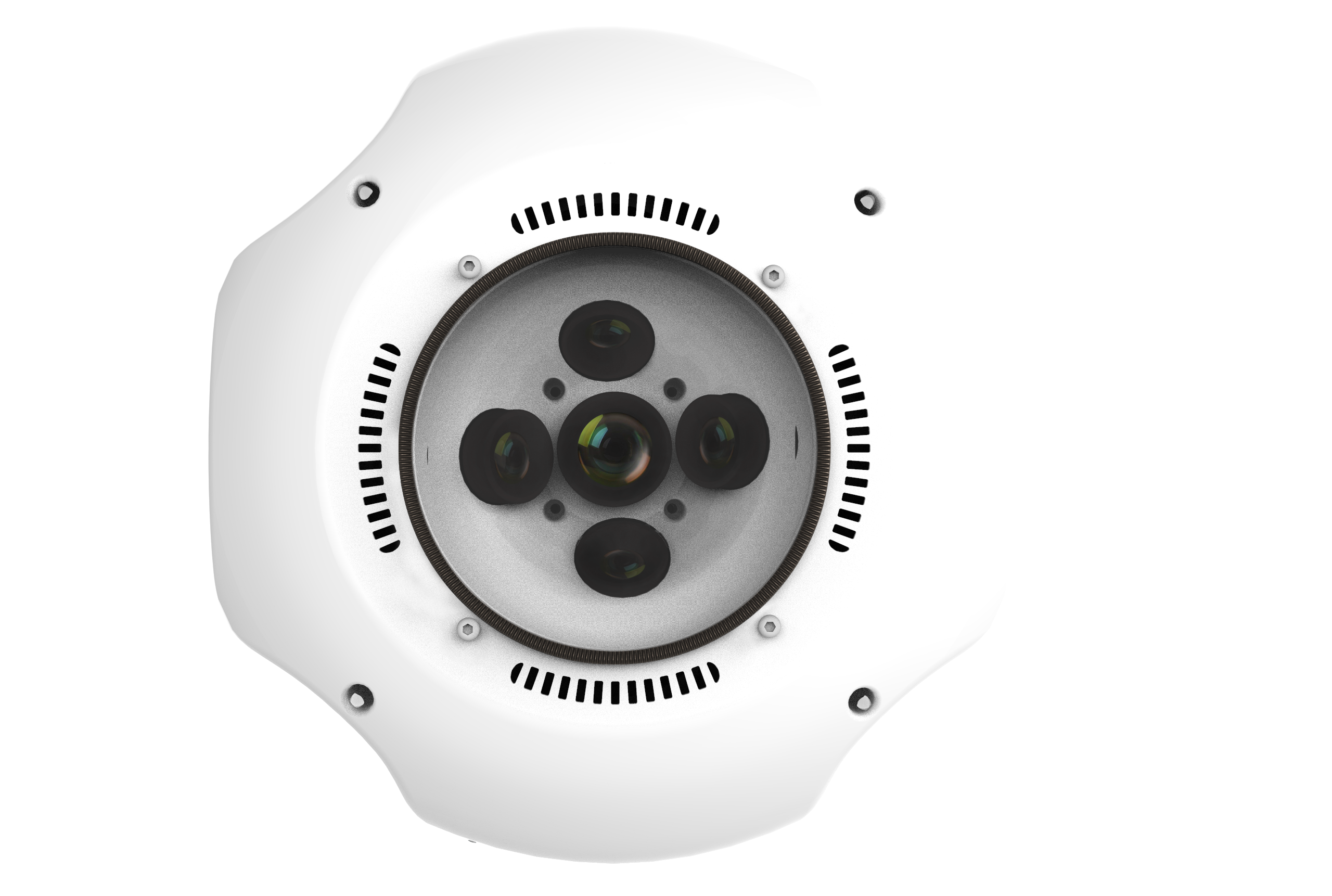

Third generation lens set |

A new generation of image processors |

|

|

|

|

More reliable hardware |

Multi-model compatibility |

High-speed data export |

|

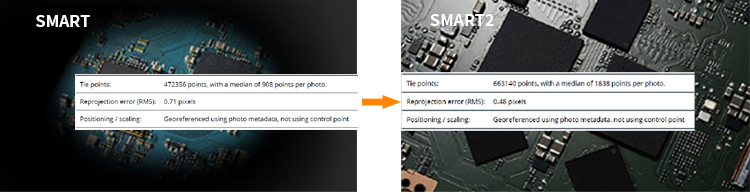

New and upgraded image sensor is used to make the image quality more delicate and color restoration more accurate Compared with the previous generation, the connection point of empty three calculation is up to 40% higher, and the model accuracy is further improved At the same time, the supported camera frequency has been increased to 0.2 seconds

|

|

|

Lens optical optimization |

|

Equipped with a third generation lens Lower dispersion lens sets and UV filters Higher lens consistency and distortion - free design Factory after internal and external field double calibration

|

|

|

|

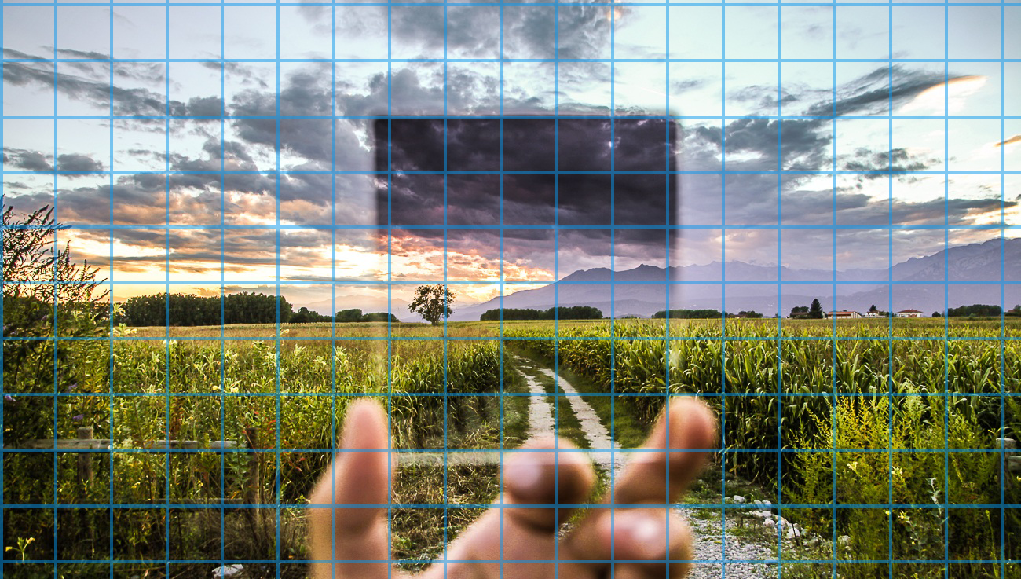

25 medium view 35mm side-view lens group configuration, can ensure nearly 100% coverage of ground imaging, and at any altitude in the forward camera and tilt camera data acquisition resolution is consistent, to avoid a single route collection blind area/different data acquisition resolution. |

|

|

|

|

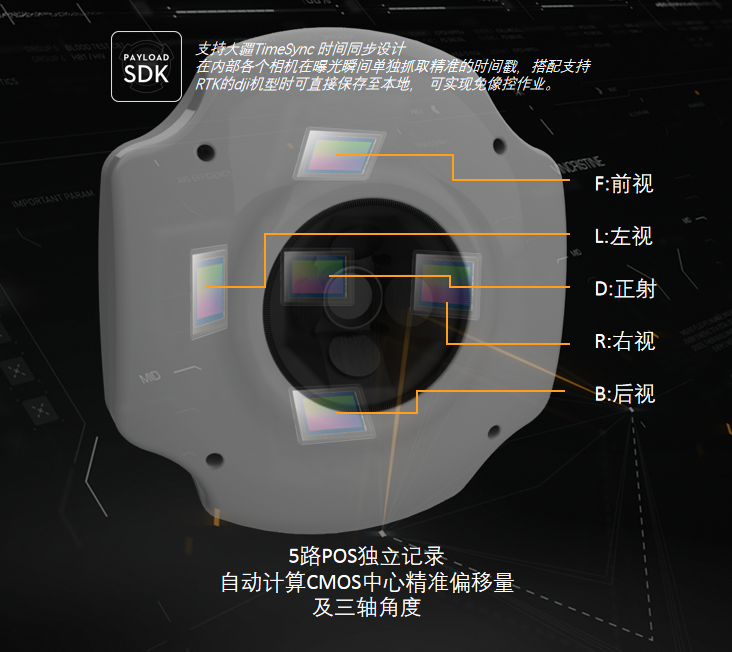

TimeSync is a continuous synchronous flight control, camera, GPS module, RTK module, DJI load and on-board accessories clock system built by DJI DJI innovation.

This enables Smart2 compatible with the DJI PayloadSDK ecosystem to communicate with the DJI flight platform in real time for clock signal synchronization.

At the same time, the high-precision positioning information of airborne RTK can be captured independently at the moment of taking pictures with cameras in all directions.

The time error is less than 1ms, and the comprehensive actual positioning error is 0.8cm. So that image-free field acquisition can be realized. Meet the large range of tilt photography high-precision acquisition operations.

|

|

|

|

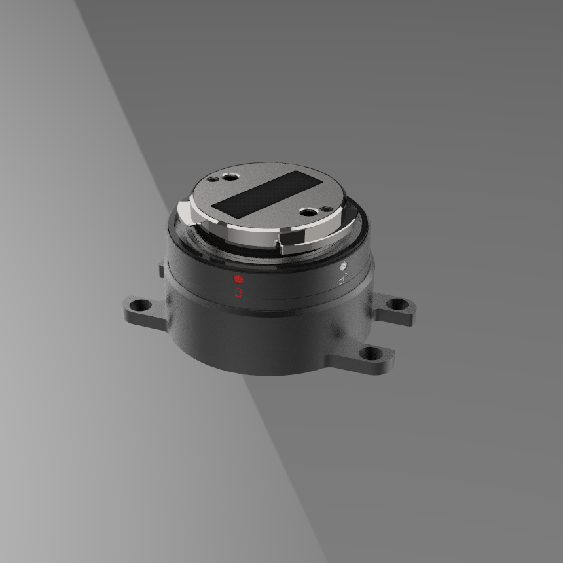

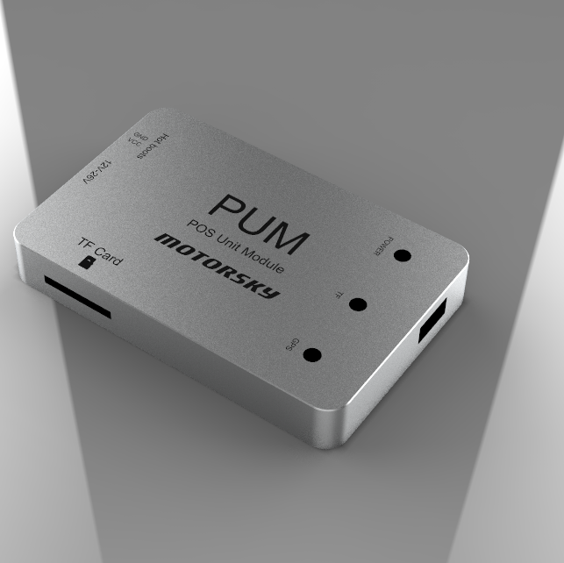

Smart-2 can be additionally configured with a separate POS recording module

Complete POS information recording without being affected by flight platform performance

|

|

|

|

|

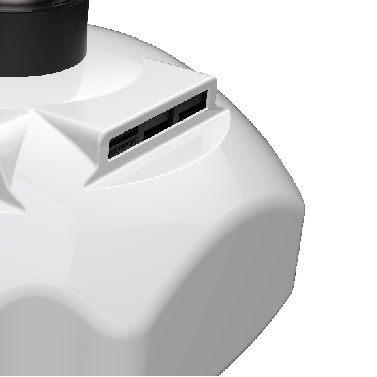

The drag coefficient is particularly important for the endurance performance of the rotary-wing UAV platform Smart2 in the fixed wing and other internal cabin installation flight platform installation conditions while Drag factor considerations are incorporated into the shell design The overall shape is streamlined, with a smooth housing and large leading edge radius It can reduce the differential pressure resistance of the UAV when the external equipment flies, and provide longer endurance |

|

|

|

A more refined figure It can be paired with a smaller flying platform Built-in exquisite structure Achieve more extreme lightness

|

|

|

Greater environmental adaptability

|

|

The optimized design of SMART2 products provides lower operating calorific output

Can avoid the complex active air cooling cooling and solve the problem of waterproof and dustproof.

- Adapt to a wider range of operating environments

|

|

Rich accessories are more possible

|

|

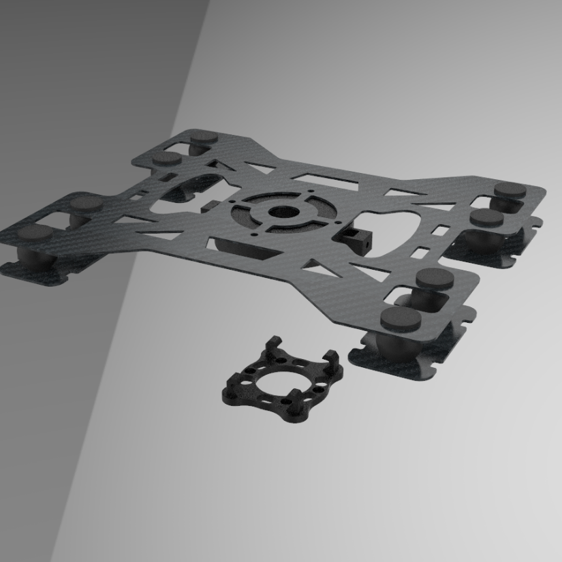

PSDK high precision positioning module Load damping assembly Mount the shock absorber assembly PAUM module Data export Hub module External PPK module And so on.. |

|

PSDK high precision positioning module |

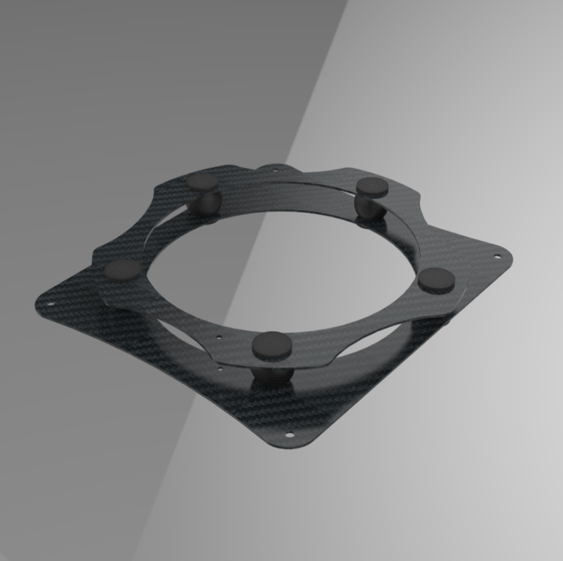

Mount the shock absorber assembly |

Load damping assembly |

PAUM module

|

|

More extension accessories are continuously updated...… |

|

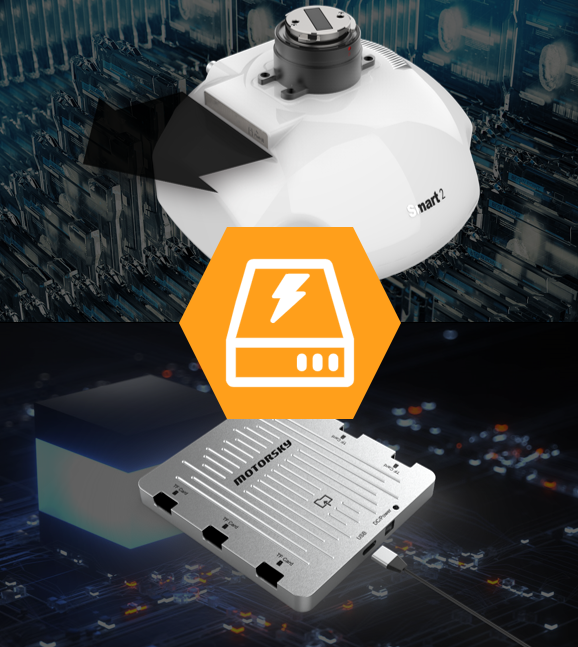

Pluggable high-speed data transmission mode

|

|

Smart-2 is the way to copy and export data from the previous independent HUB module To use high-performance solid-state detachable storage modules, support rapid reloading, two storage modules can achieve uninterrupted flight acquisition, without waiting for data export.

- Supports high-speed data transmission up to 200Mb /S

|

|

|

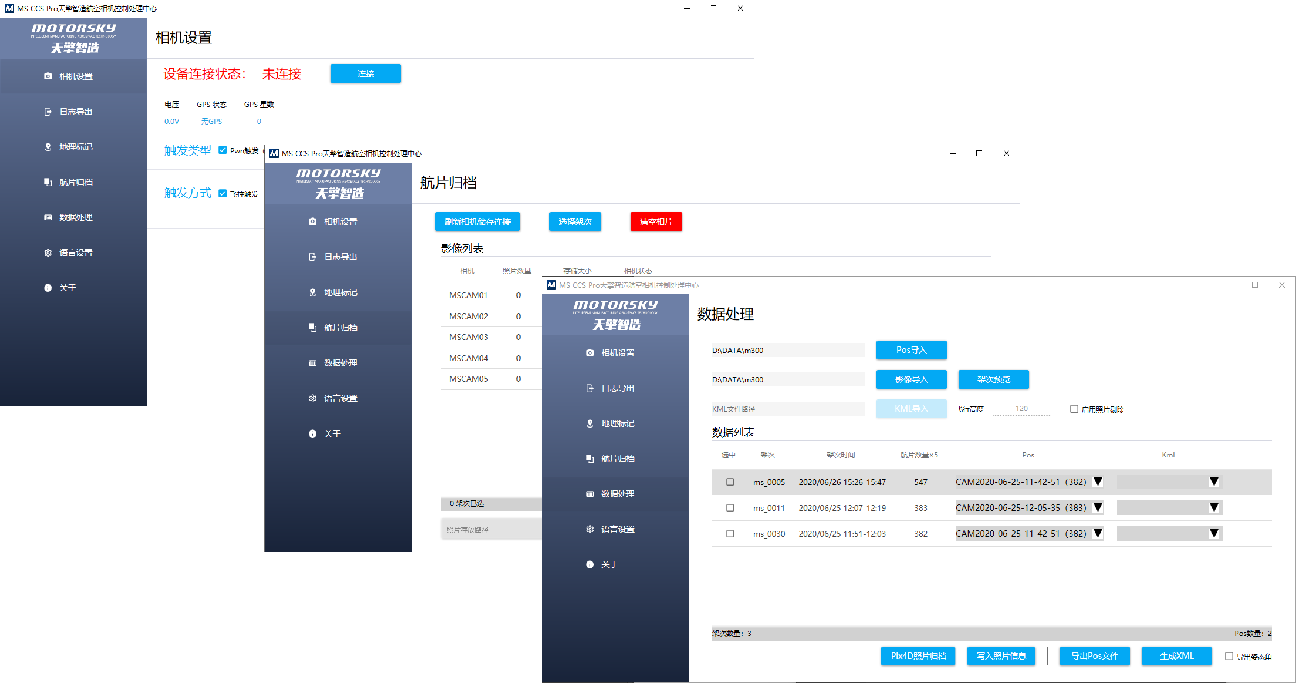

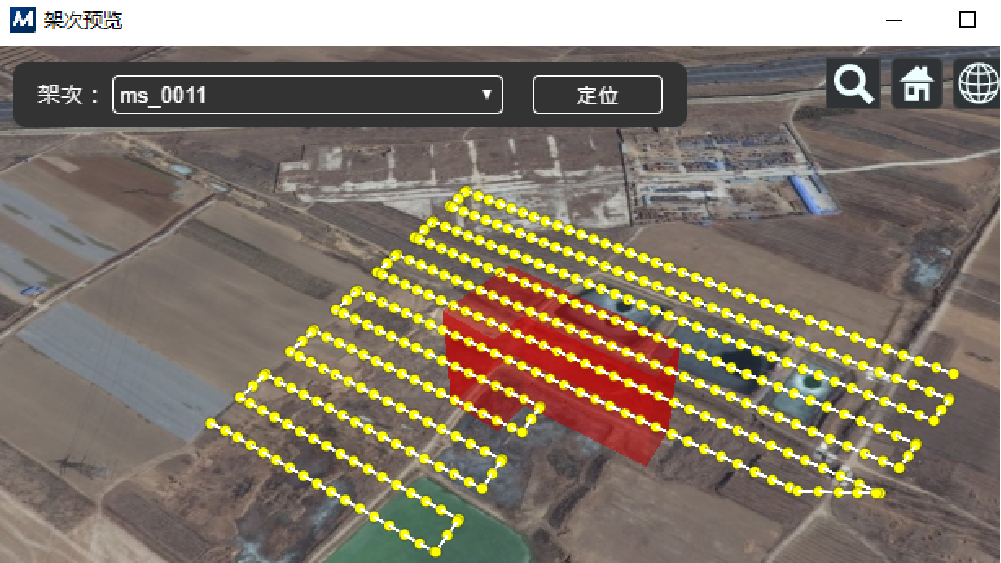

MS CCS Pro uses 3D engine data preprocessing software |

|

MS CCS Pro is for MS-Smart tilt camera matching for corresponding data export And the pre-processing software of the late data processing, It can realize the whole process from image processing to XML configuration file generation of reconstruction software.

|

|

|

|

After completion of the field operation, data can be automatically exported according to sorties and camera direction without manual intervention; It supports POS information of various formats for photo matching, and then automatically eliminates the useless aerial photos, directly generates block files, and directly imports them into the later software to start reconstruction. (Save 90% of manual operation time between field data processing and internal processing) |

|