|

FARO® Vantage Laser Trackers

Measuring large parts, molds, assemblies and machines used to be a difficult, time-consuming process that often required special testing areas. The portable FARO Vantage Laser tracker makes field measurements easy and fast, reducing inspection cycles by up to 75%. They measure three-dimensional coordinates by tracking the target as the user moves from one point to another on the measuring object. It only takes a few seconds to compare these measurements to nominal CAD data so that the team can make informed adjustments or move forward with confidence.

|

|

|

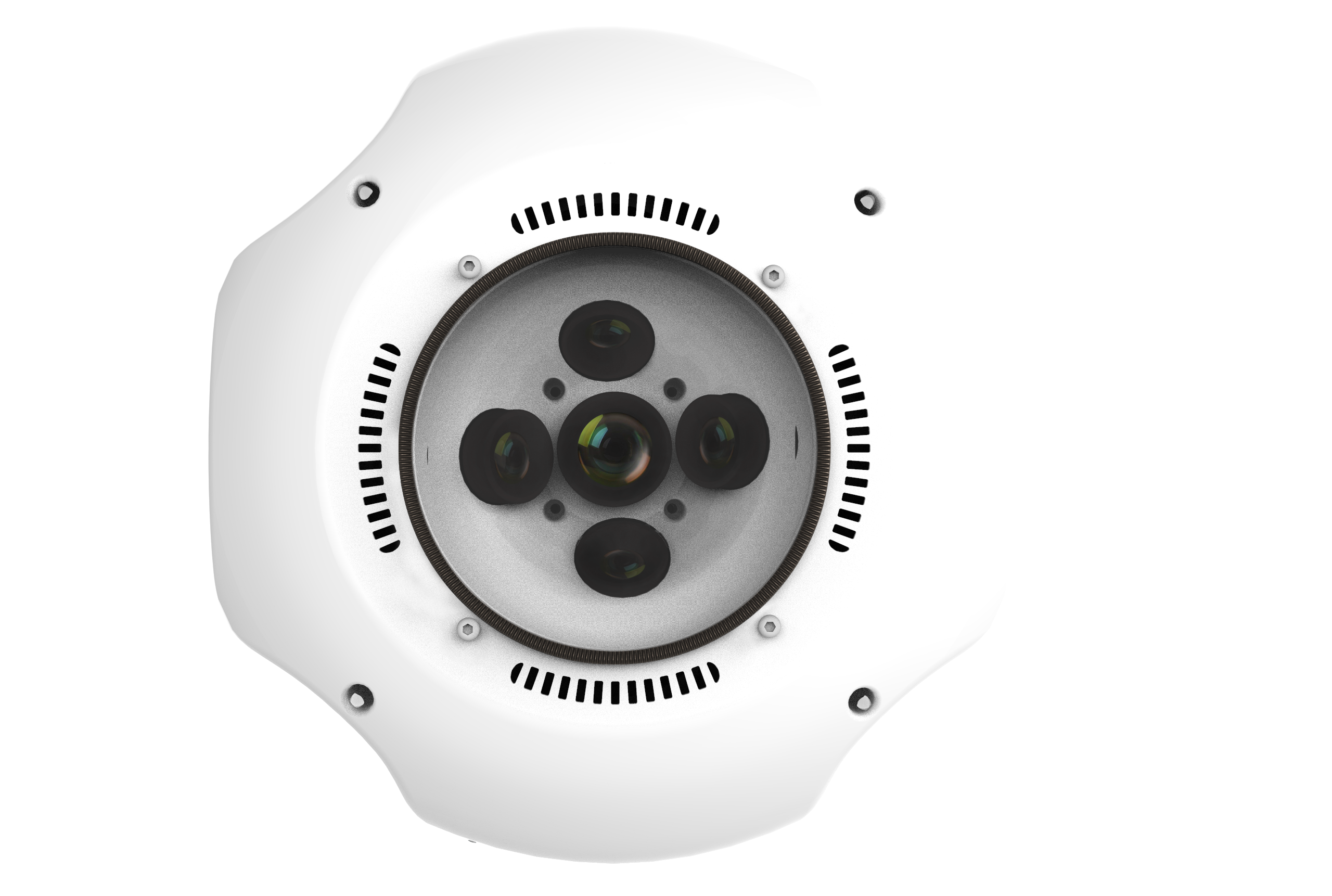

ActiveSeekTM Technology Even after the obstacle can follow the moving target, with a wide field of vision in the industry. |

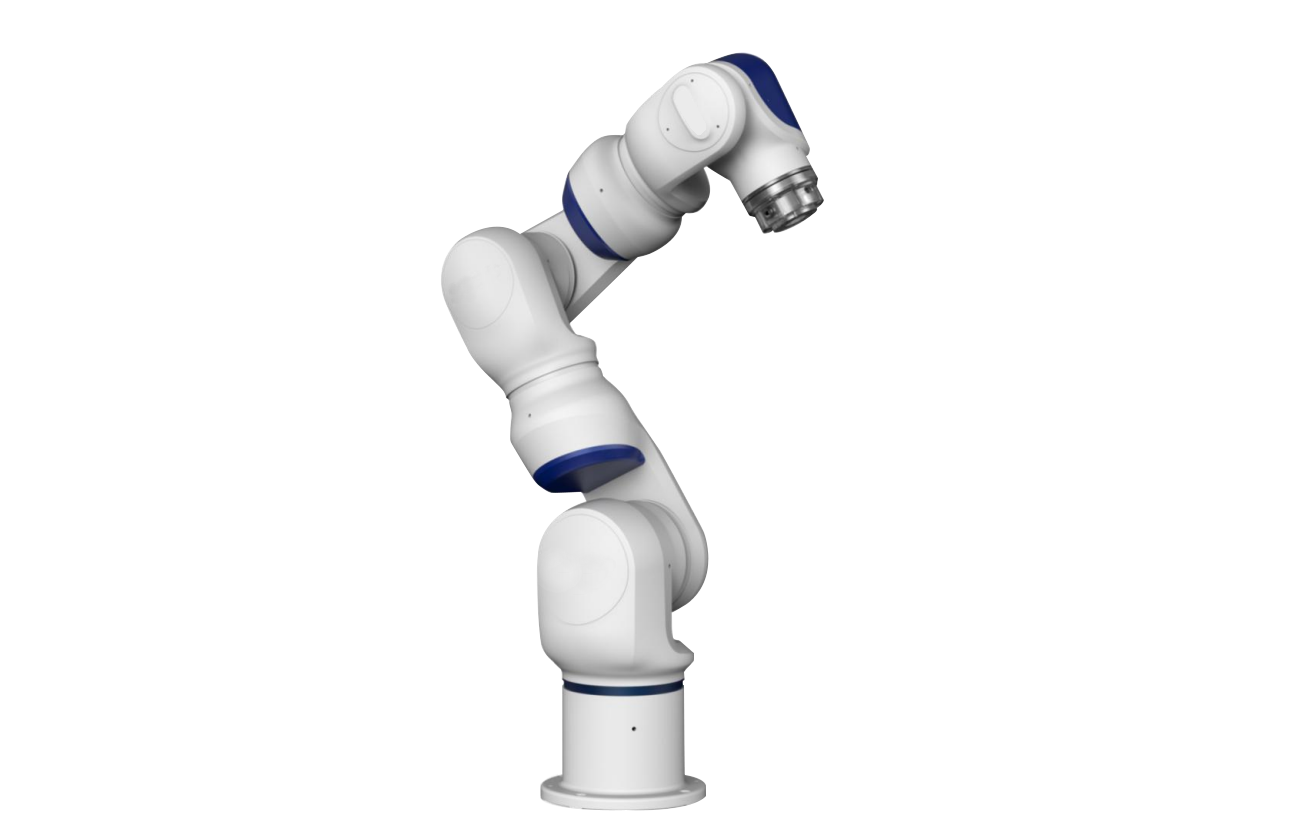

6Probe

6DoF measurements are performed using a hand-held 6Probe with interchangeable needle, capable of measuring hidden areas out of sight.

|

Fast data acquisition

Fast capture of data for high speed motion control and high density scanning.

|

Integrated High Precision Distance Measurement System (iADM)

A single beam Level 1 (eye safety) laser system is used to ensure reliable measurement of distance and Angle.

|

RemoteControlsTM Workflow software

The laser tracker is controlled by mobile device.

|

Portability

Suitable for all kinds of environment, transport is also very convenient.

|

|

|

Hot swap battery

Just change the battery to run continuously.

|

Integrated Wi-Fi

Operate without any cables.

|

Multi-purpose installation

It can be installed in almost any configuration.

|

|

Integrated weather stationAccuracy can be ensured in all atmospheric conditions. |

|

3D measurement applications |

Accurate mass productionEnsure equipment alignment and adherence to strict tolerances when producing large parts, guide assemblies, calibrating robots and tooling. From aerospace to shipbuilding, innovative industries rely on FARO's Vantage Laser Tracker to produce components, assemblies and composites at high speeds and with accuracy. |

Strengthen the quality control of large partsDetection of large components and assemblies, as well as composites, is up to 75% faster than conventional measurement methods. The Vantage Laser Tracker provides complete quality assurance by generating digital records of both actual and nominal data to verify compliance with specifications. |

Speed up the engineering of large components and assembliesUse the Vantage Laser Tracker to speed up the design process and product improvement plans. Whether using spare parts or recording finished products and molds, the Vantage tracker ensures accuracy during rapid prototyping and is well integrated with reverse engineering software. |