|

No Record

|

|

- Home

- About us

- Hardware

-

Artec 3D scanner

Artec Eva

Artec Space Spider

Artec Leo

Artec Ray II

Artec Micro

Artec 3D scanner

Artec Eva

Artec Space Spider

Artec Leo

Artec Ray II

Artec Micro

-

Faro 3D laser scanner

FARO® Focus Premium

FARO FocusM 70

FARO FREESTYLE 2

Faro 3D laser scanner

FARO® Focus Premium

FARO FocusM 70

FARO FREESTYLE 2

-

Faro industrial reverse scanner

FARO® Quantum Max ScanArms

Quantum Max FaroArm

Faro industrial reverse scanner

FARO® Quantum Max ScanArms

Quantum Max FaroArm

-

FARO® Vantage Laser Trackers

FARO® Vantage Laser Trackers

FARO® Vantage Laser Trackers

FARO® Vantage Laser Trackers

-

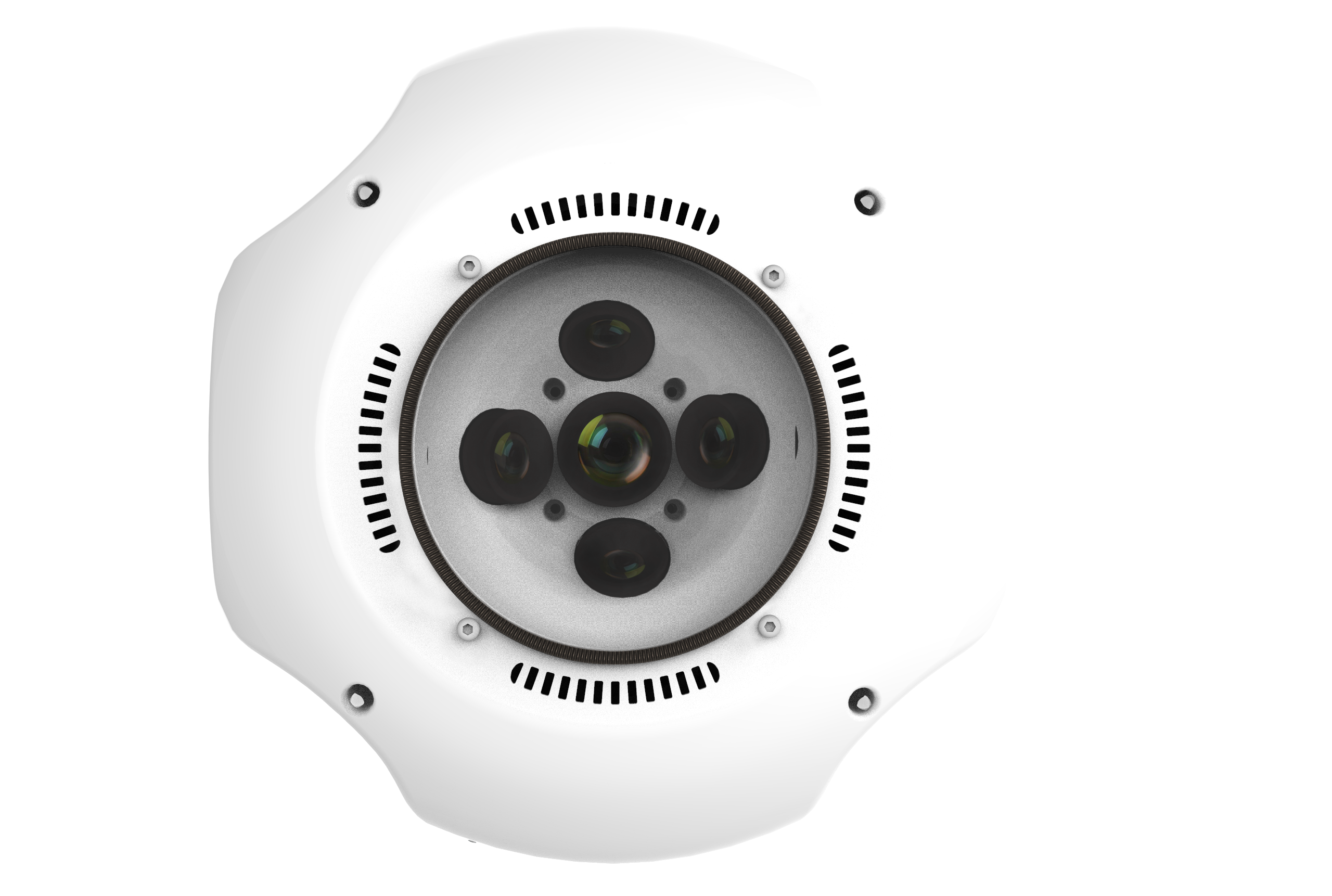

UAV Tilt photography

MS-Smart 2

UAV Tilt photography

MS-Smart 2

-

RIEGL Terrestrial Laser Scanning

RIEGL VZ-400i

RIEGL VZ-2000i

RIEGL VZ-4000

RIEGL VZ-6000

RIEGL Terrestrial Laser Scanning

RIEGL VZ-400i

RIEGL VZ-2000i

RIEGL VZ-4000

RIEGL VZ-6000

-

GoSLAM

GoSLAM VS120

GoSLAM RS100S

GoSLAM RS100i

GoSLAM DS100

GoSLAM RS100

GoSLAM VS100

GoSLAM

GoSLAM VS120

GoSLAM RS100S

GoSLAM RS100i

GoSLAM DS100

GoSLAM RS100

GoSLAM VS100

-

High resolution aerial camera

Phase One iXU 180

Phase One iXU 150

High resolution aerial camera

Phase One iXU 180

Phase One iXU 150

-

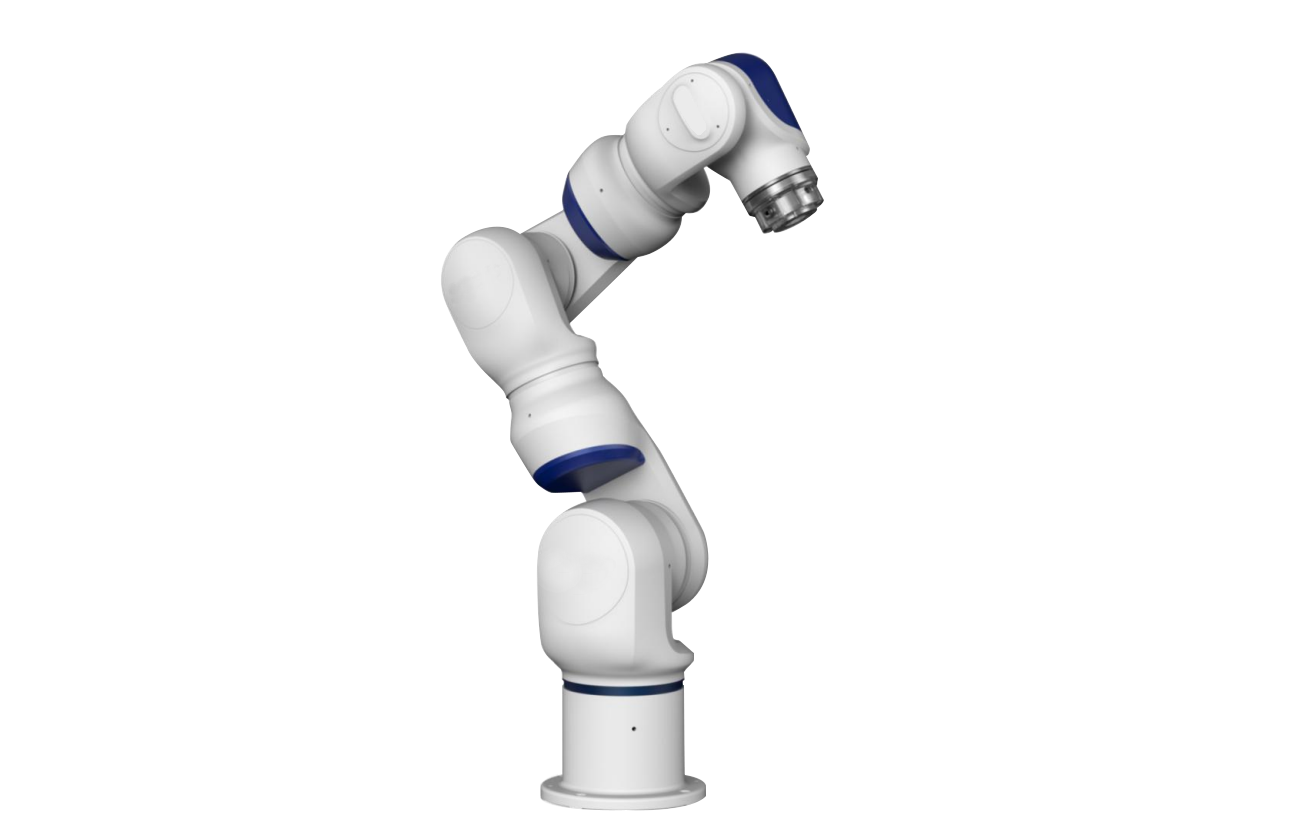

Collaborative robot

Collaborative robot

Collaborative robot

Collaborative robot

-

3D Lidar

OS1 Lidar

3D Lidar

OS1 Lidar

-

3D scanner accessories

标靶球(配准)

棱镜球(配准)

TSP定位装置

3D scanner accessories

标靶球(配准)

棱镜球(配准)

TSP定位装置

-

ATS positioning registration kit

ATS positioning registration kit

ATS positioning registration kit

ATS positioning registration kit

-

- Software

-

Faro software

AS-BUILT FOR AUTOCAD®

AS-BUILT FOR REVIT®

FARO Scene2019

BuildIT Construction

Faro software

AS-BUILT FOR AUTOCAD®

AS-BUILT FOR REVIT®

FARO Scene2019

BuildIT Construction

-

Clear Edge software

EdgeWise Plant

EdgeWise MEP For Revit

EdgeWise Building

EdgeWise Structure

ClearEdge Verity

Clear Edge software

EdgeWise Plant

EdgeWise MEP For Revit

EdgeWise Building

EdgeWise Structure

ClearEdge Verity

-

3D Reshaper software

3D Reshaper

3D Reshaper LSDK

3D Reshaper software

3D Reshaper

3D Reshaper LSDK

-

Arena4D

Arena4D

Arena4D

Arena4D

-

Artec post-processing software

Artec Studio 14

Artec Studio 15

Artec Studio 17

Artec post-processing software

Artec Studio 14

Artec Studio 15

Artec Studio 17

-

PhotoScan software

PhotoScan software

PhotoScan software

PhotoScan software

-

Onrol products

空间数据浏览器

激光雷达综合应用平台

Onrol products

空间数据浏览器

激光雷达综合应用平台

-

- Application

-

Building and engineering

City planning

Digital City

Tunnel engineering

Highway acceptance

Settlement monitoring

Building structure safety inspection

Urban disaster analysis

Bridge reconstruction

railway construction

Airport and port

Building and engineering

City planning

Digital City

Tunnel engineering

Highway acceptance

Settlement monitoring

Building structure safety inspection

Urban disaster analysis

Bridge reconstruction

railway construction

Airport and port

-

Cultural heritage protection

Ancient architecture protection

Site excavation protection

Paleontological record

Digital Museum

Cultural heritage protection

Ancient architecture protection

Site excavation protection

Paleontological record

Digital Museum

-

Geological and scientific applications

Terrain Surveying

Landslide monitoring

Mining operation

Forest green quantity

Geological and scientific applications

Terrain Surveying

Landslide monitoring

Mining operation

Forest green quantity

-

Electricity and water application

Substation

Power line inspection

Reservoir and dam

Electricity and water application

Substation

Power line inspection

Reservoir and dam

-

Manufacturing and digital factory

Plant facilities

Detection and reverse engineering

Aviation and shipbuilding

Manufacturing and digital factory

Plant facilities

Detection and reverse engineering

Aviation and shipbuilding

-

Public security application

Traffic accident

Crime scene

Public security application

Traffic accident

Crime scene

-

- Case

- Cooperation

- Support

- Download

- Train

No Record

Summary

Parameters

Video

Download

Hardware

Artec 3D scanner

Faro 3D laser scan

Faro industrial re

FARO® Vantage

UAV Tilt photograp

RIEGL Terrestrial

GoSLAM

GoSLAM VS120

GoSLAM RS100S

GoSLAM RS100i

GoSLAM DS100

GoSLAM RS100

GoSLAM VS100

GoSLAM RS300

GoSLAM RS100 RTK

High resolution ae

Collaborative robo

3D Lidar

3D scanner accesso

ATS positioning re

About us

Cooperation

Software

- Faro software

- Clear Edge software

- 3D Reshaper software

- Arena4D

- Artec post-processing software

- PhotoScan software

- Onrol products

Support

Hardware

Application

Copyright(c)2015 Beijing Onrol Technology Co.ItdAllright Reserved