|

FARO® Quantum Max ScanArms

FARO® Quantum Max ScanArmsThe global standard in non-contact measurement arm technology

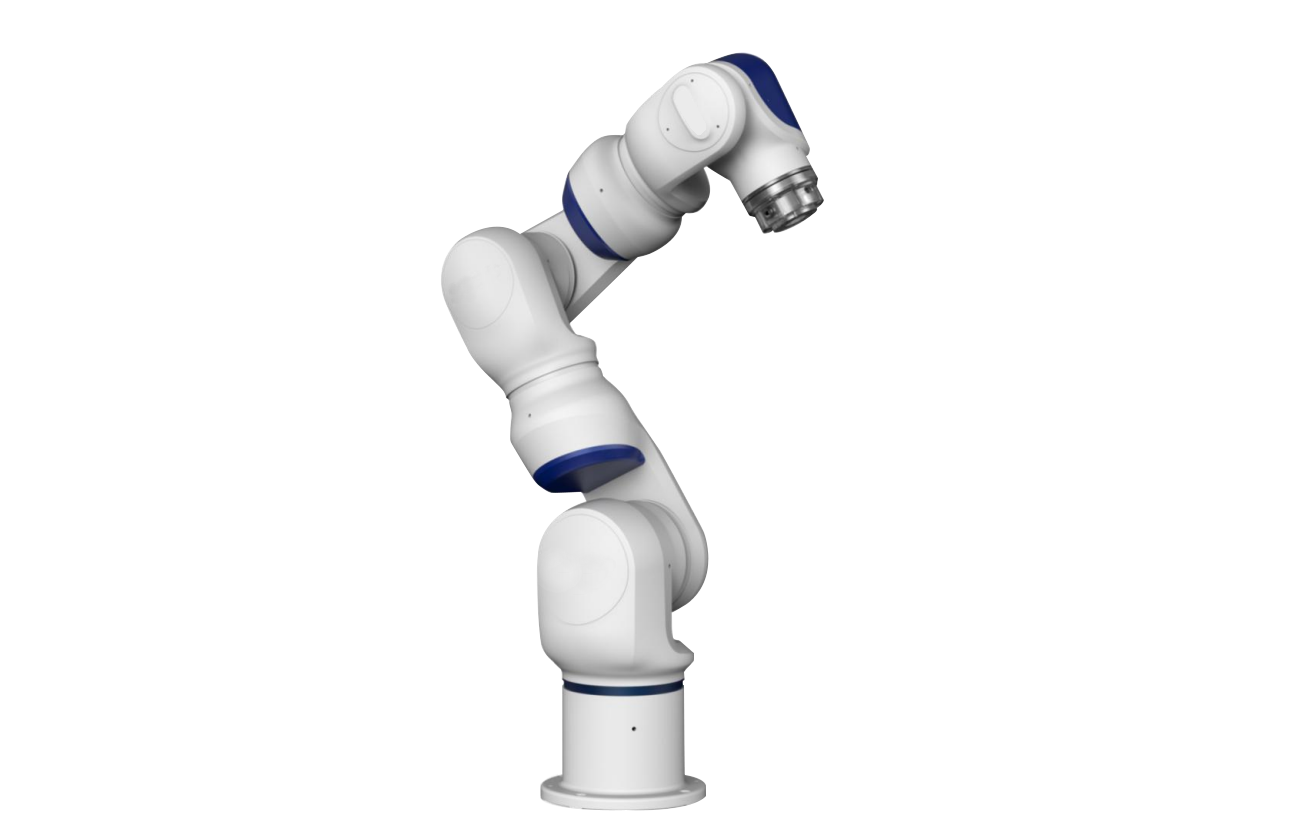

Sometimes a part or tool is so complex, you can’t use contact probes to capture all of its measurements. But lasers do the job with exceptional speed and accuracy. In these cases, leading manufacturers rely on FARO Quantum Max ScanArms, which combine the measurement capabilities of a Quantum Max FaroArm® portable coordinate measuring machine (CMM) with the non-contact functionality of a laser line probe. The Quantum Max also offers three LLPs that optimize accuracy, speed or a blend of both, depending on project need. Whichever LLP you choose, 3D ScanArms capture precise measurements in nearly any environment, from the factory floor to the field. |

|

3 Purpose-Built LLPs

Now the tradition continues with the all-new Quantum Max ScanArm and its three hot-swappable FAROBlu® LLPs that meet any measurement need.With options to dramatically increase the scanning speed or resolution, getting the job done as quickly and precisely as possible has never been easier.

With maximum flexibility, extended arm reach and a redesigned end effector with dual kinematic LLP mounts, value and productivity is maximized by over 30%.

The Quantum Max features the fastest, most detailed scanning available on the market today, accelerating project completion time while enhancing overall productivity.

Maximum Versatility

The new Quantum Max offers 2 times the versatility from previous models. Dual kinematic seats allow for hard probe and LLP interchangeable mounting positions to easily move the LLP from top to front mount, enabling greater access to small spacesor hard to reach areas without the need to recalibrate. The quick release handle also offers dynamic holding options.

Maximum Performance

Three FaroArm models offer basic, standard, and premium performance options—available in various working volumes from 2.0m to 4.0m. Improved rigidity and stability deliver optimized accuracyand repeatability with superior performance while maintaining shop-hardened ruggedness for use

in the harshest factory environments. The new 2.0m working volume arm delivers the best accuracy in its size category.

Maximum Reach

Each FaroArm model comes with up to 25% longer reach, offering more comfortable articulation for better extension over and around larger objects positioned within its specified working volume.Maximize

value and productivity by over30%

Combined with the FARO exclusive 8-Axis Max rotary worktable, the need to relocate or reposition the device is virtually eliminated—and inspections can be completed in a fraction of the time.

The right LLP is not always a “one size fits all” choice. Sometimes the fastest speed is needed to get the job done quickly. Sometimes the highest accuracy and resolution possible is needed instead. And

sometimes, a trade-off of both is preferred. With the Quantum Max, choosing between these options is now seamless. Three unique models help boost productivity collectively or individually. All LLPs come with the exclusive FARO Continuous Light Rectifications (CLR) scanning technology, providing users with the highest quality scan data possible on dark, translucent, and reflective surfaces.

Quantum Max LLPs

With the next-gen Quantum Max, getting the inspection job done as quickly and precisely as possible has never been easier when using multiple LLPs thatcan be changed in seconds, with no need for recalibration so inspection can continue, virtually uninterrupted.

SmartFactory Ready

Every operator can now perform the exact same inspection routine, thus minimizing variability and maximizing repeatability. Data records are digitally stored, analyzed, and maintained so trends can be identified and appropriate actions are taken when parts begin to deviate from their nominal tolerances.

Business Value of ScanArms

Scan More, Scan Better, Scan Faster

Increase your productivity without the need to compromise between speed and accuracy.Ensure Consistency and Repeatability

Every operator gets the same results every time.Optimize Operations

Precision measurement reduces scrap, rework and inspection bottlenecks.Capture Production Data

Accurate data allows for reporting and trend analysis.Improve Quality

Complex 3D inspections and automatic reports help users pinpoint defects.Capture Details

The FARO laser ScanArm captures extreme measurement detail on complicated parts and objects.Enhance Yield

Faster troubleshooting and root-cause analysis help increase overall yield.Increase Throughput

Higher production rates and reduced downtime for verification mean greater throughput.Accelerate Revenue Generation

You’ll bring products to market faster and reduce rework and downtime.Keep Customers and End Users Happy

Delivering higher-quality products that can be used with confidence makes everyone happy and keeps customers loyal.Make Informed Decisions

With the information at your team’s fingertips, they’ll be equipped to make smarter decisions faster and stay ahead of any problems.

ScanArms By Performance Level

QUANTUM MAX SCANARMS

Maximum Performance

QuantumS is the flagship measurement arm, delivering premium accuracy and performance. QuantumM provides the global standard in portable metrology and boasts an ideal price/performance ratio, well suited for factory inspection tasks. QuantumE offers excellent performance at a competitive price and ensures high-quality production.

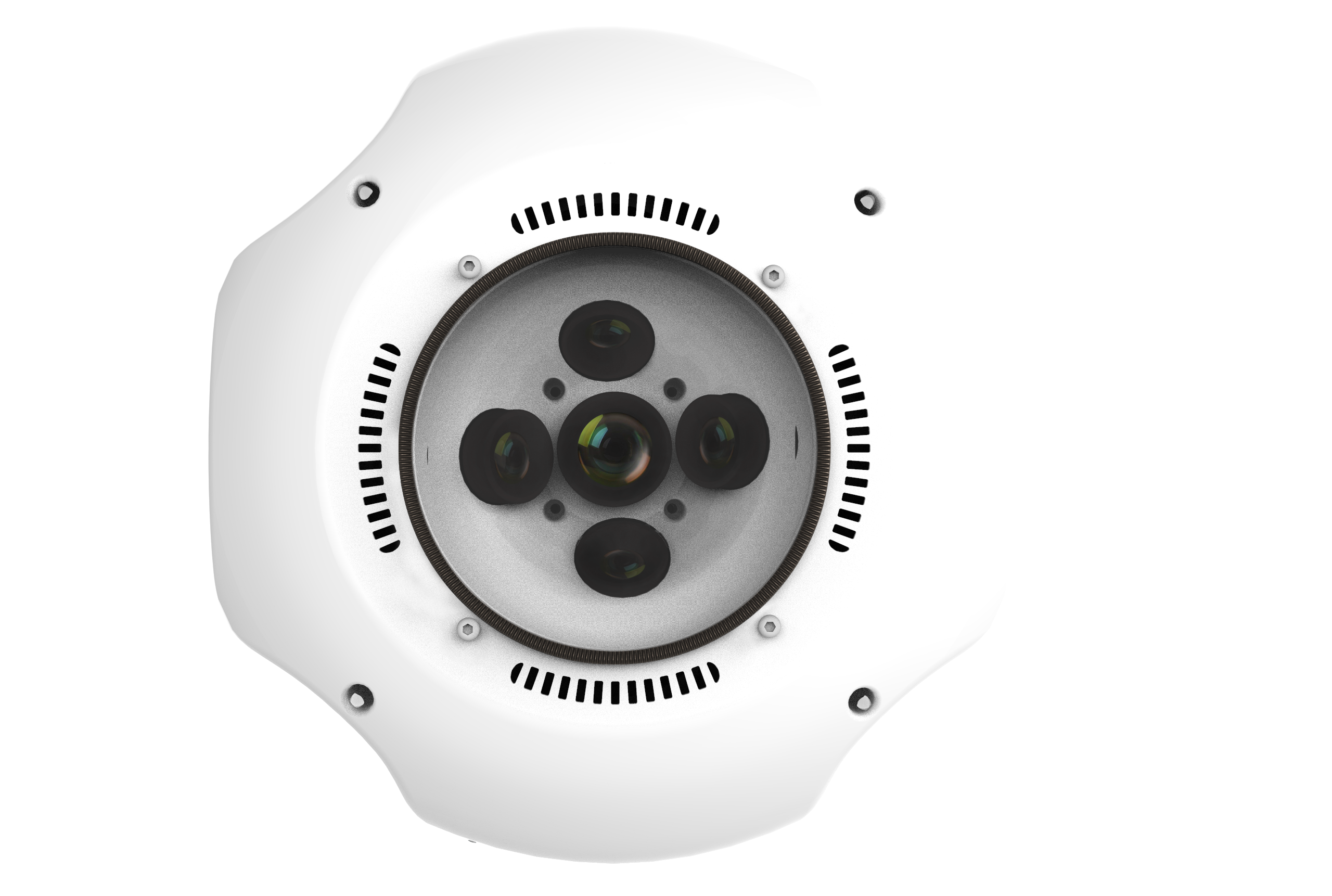

FAROBLU XR

Maximum Resolution & Accuracy

This Laser Line Probe (LLP) is ideal for high-precision tasks with tight tolerances to capture data at highest accuracy and best resolution possible. Users can scan small intricate parts and fine details with 1.5 times the accuracy, improving production quality with better and more reliable data.

FAROBLU XP

Maximum Productivity

This Laser Line Probe (LLP) offers the ability to scan anything with a balanced blend of accuracy, speed and coverage—increasing profitability and throughput with performance suitable for any application.

FAROBLU XS

Maximum Speed

This Laser Line Probe (LLP) is best for large parts or expansive surface areas when data collection speed is top priority. The extra‑wide laser stripe delivers double the coverage in a single pass, allowing users to collect data up to 2.6x faster than the xR and 1.6X faster than the xP. Fewer passes to collect data means faster results and higher productivity.

8-AXIS SCANNING PLATFORM

8-Axis Scanning Platform: Faster Scanning with Any Quantum V2 ScanArm

An industry first, the integrated 8-axis rotary scanning platform decreases scan time by up to 40%, while maintaining accuracy. The platform is available with all ScanArm models; select the 8-Axis QuantumS ScanArm, 8-Axis QuantumM ScanArm or the 8-Axis QuantumE ScanArm.

ScanArm Features

Family of Laser Line Probes (LLPs)

Achieve high-speed point cloud capture, high accuracy or a blend of both with three LLPs, each hot swappable and purpose built.Multiple Working Volumes

Meet the needs of any application with working volumes of 2.0m, 2.5m, 3m, 3.5m and 4m.Continuous Light Rectification (CLR) Technology

Scan dark, reflective or translucent surfaces.Smart Probe Capability

Quickly and easily change probes without recalibration.Internal Counterbalancing

Operate with a single hand and without fatigue.Ergonomic Design

Transport, set up and operate ScanArms with ease and comfort.

Exclusive 8-axis Integration

Quickly measure all sides of a part without repositioning.Compliance

Meet rigorous ISO 10360-12 accuracy standards.Universal Quick Mount

Set up a ScanArm wherever it’s needed.Temperature and Overload Sensors

Ensure continuous, optimum performance.Powerful Software Solutions

Easily integrate ScanArms and software.Extended Battery Use Option

Operate without cables.High-speed Wireless Operation

Connect with Bluetooth or Wi-Fi.Rugged Design

Use ScanArms even in the most challenging measurement environments.

3D Metrology Applications

Improved Quality Control and Inspection

Verify dimensional accuracy and identify deviations from nominal CAD data during first-article and in-process inspection, as well as inspection of incoming parts.Production, Fabrication and Assembly

Keep production machinery calibrated and aligned, and verify dimensional accuracy of tooling and parts.Faster, More Accurate Product Design and Engineering

Expedite reverse-engineering and rapid prototyping for shorter time to market.