|

Artec Micro

Professional ultra-high-precision industrial desktop 3D scanner for small machine parts, jewelry and dentistry

|

|

This fully-automated desktop 3D scanner was designed to deliver industrial-quality scans with just one click. Perfect for reverse engineering small objects, quality control, inspection, dentistry, jewelry, design, and more, Artec Micro scans with a point accuracy of up to 10 microns. Created with ease-of-use and precision in mind, Artec Micro brings the ultimate scanning solution right to your desktop.

|

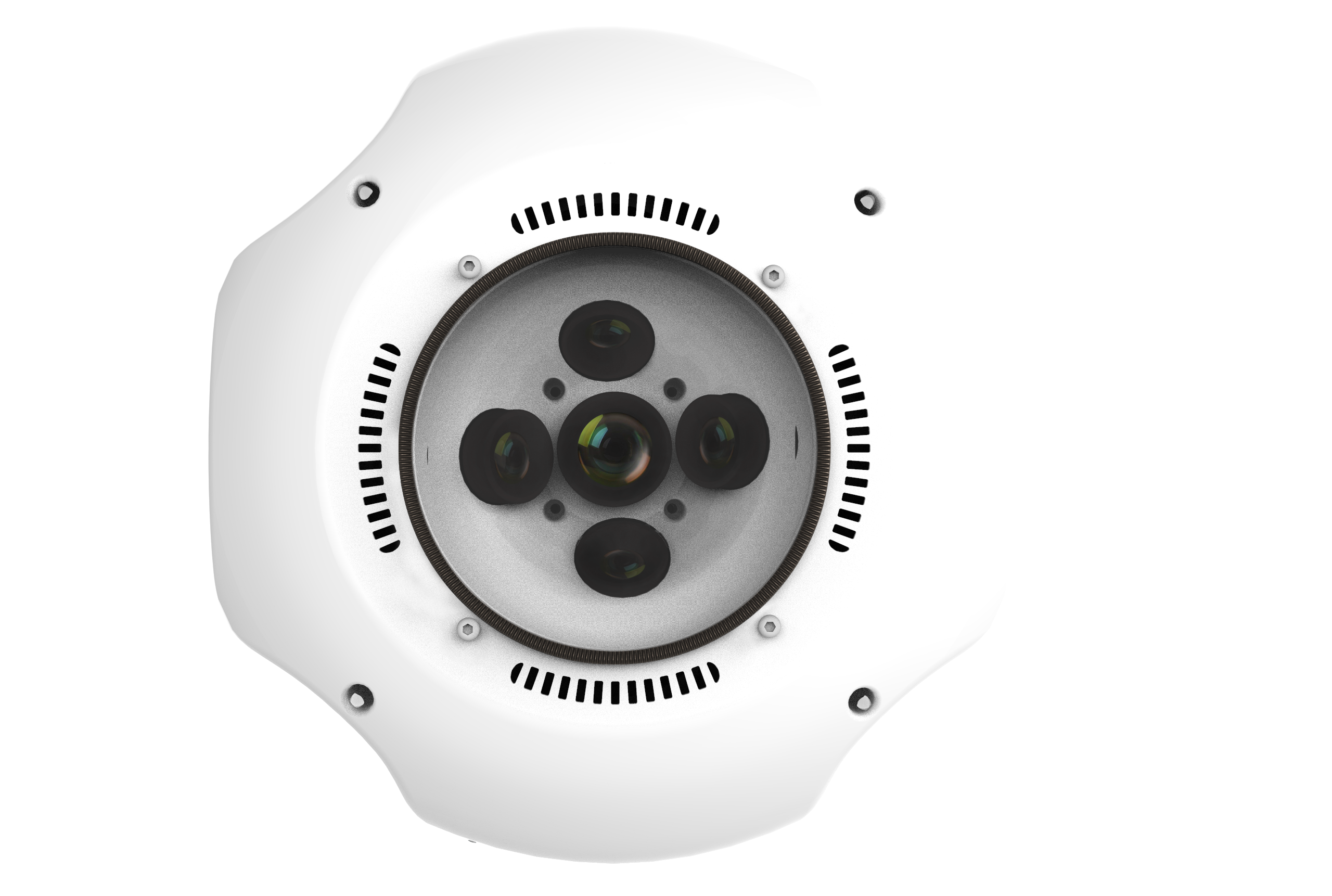

The cutting edge of desktop 3D scanningArtec Micro brings the latest in scanning technology to your desktop. Its advanced twin color cameras and blue LED lights are perfectly synchronized with Micro’s dual-axis rotation system (swing & rotation) to create the ultimate digital copy of your object with a minimum of frames captured. |

|

|

|

|

|

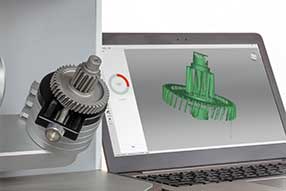

Powerful, robust softwareRight out of the box, Micro integrates with the industry-acclaimed Artec Studio for real-time digital capture. See your scans coming to life on the screen. After scanning, Artec Studio makes it easy for you to process your scan. Simply follow the same series of steps as you would with our handheld scanners, and then export the final 3D model to software such as SOLIDWORKS, PolyWorks Inspector, Control X or Design X. |

Applications |

|

|

|

Quality inspectionAcross a variety of industries, there is a growing need for ensuring that product quality levels are as high as possible. Delivering metrology-grade scans at up to 10 microns’ accuracy (0.4 thou), not only can Micro “see” well below the human visibility threshold of 40 microns, but its 3D measurements are among the best in today’s cutting edge scanners, making it a perfect choice for inspection and much more. |

|

|

Reverse engineeringWhether you have a small part to reproduce for which no blueprint exists, or you need to quickly redesign or simply modify an existing part and either mill or 3D print it, Artec Micro can do the job. Small parts can be a real challenge for handheld scanners, but Micro was created for exactly this. Its precise 3D measurement allows you to digitally fit together legacy parts with those you’re creating, capturing even the finest details that most other scanners will miss. Accelerate your design, prototype, and production cycle by weeks and save thousands in the process.

|

|

|

JewelryForget about the traditional method of calipers and tracing methods. In minutes, Artec Micro transforms intricate jewelry items into CAD/CAM data for design, modification, 3D printing, and casting. Saves hours of time in the design and production of complex and highly-detailed jewelry pieces. Create custom-fitting wedding bands from engagement rings in a matter of hours rather than days. Update family heirlooms by taking an existing diamond or stone and creating an entirely new jewelry piece to perfectly complement it. |

|

|

Cultural heritage preservationToday, countless priceless historical items are locked away in museum storage or back rooms. Over time, due to improper conditions, many of these objects are deteriorating. Documenting these precious items is a race against time. Artec Micro gives you the power to make highly-detailed 3D models of small cultural objects in just minutes. From there, these models can be archived, or easily shared with researchers and others either locally or around the world, or sent to a 3D printer for printing in a variety of materials. |

|

|

DentistryArtec Micro is ready for today’s dental practice, creating precise CAD/CAM-ready 3D scans for lab use and 3D printing. Ideal for scanning single teeth, entire arches, or complex impressions. Export from Artec Studio to ExoCAD and other dental software. Perfect for making exact digital reproductions and archival copies of crowns and bridges, inlays and onlays, dentures, custom abutments, implants, and more. |

Artec官网:https://www.artec3d.com